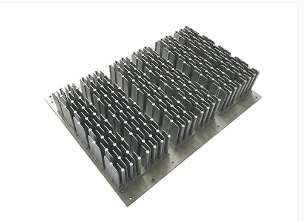

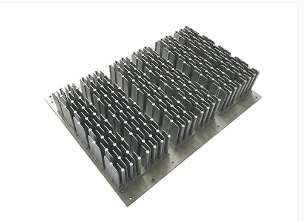

Die casting is a manufacturing process that offers numerous benefits for the production of

heat sink molds. Heat sinks are essential components in electronic devices that help dissipate heat and prevent damage to the device. Here are some advantages of die casting for heat sink mold production:

High Precision: Die casting allows for the production of heat sink molds with high precision and accuracy, ensuring consistency in the final product's dimensions and surface finish.

Cost-Effective: Die casting is a cost-effective manufacturing process, as it can produce high volumes of heat sink molds at a lower cost compared to other methods.

Efficient Production: Die casting is a highly efficient production process, as it can produce heat sink molds at a faster rate than other methods.

Versatility: Die casting can be used to produce heat sink molds of various sizes and shapes, providing versatility in design options.

Strength and Durability: Heat sink molds produced using die casting are known for their strength and durability, making them ideal for electronic devices that undergo heavy usage.

Environmentally Friendly: Die casting is an environmentally friendly manufacturing process, as it produces minimal waste and can be recycled.

In conclusion, die casting is a reliable and cost-effective manufacturing process that offers numerous advantages for the production of heat sink molds. Its precision, efficiency, and versatility make it an ideal choice for the production of heat sink molds for electronic devices.

EN

EN